Researchers make breakthrough in magnetic geometry-induced quantum geometry and nonlinear transport

2025-06-06SUSTech hosts IOP Forum with President of Institute of Physics Sir Keith Burnett

2025-03-26Researchers discover unusual thermal conductivity in high-symmetry single crystals

2025-03-26New efficient method detects quantum temporal correlations

2025-03-26Researchers explore unconventional magnons predicted by spin space groups

2025-03-25Over the last few years, techniques that convert waste energy into a storable form, particularly electricity, have become a promising and sometimes mandatory strategy for industrial and domestic utilities with the release of China’s carbon emission goals. Among them, is the rise of thermoelectric technology (TE) as a clean, quiet, and long-lasting option to other conventional techniques in converting waste heat to electricity.

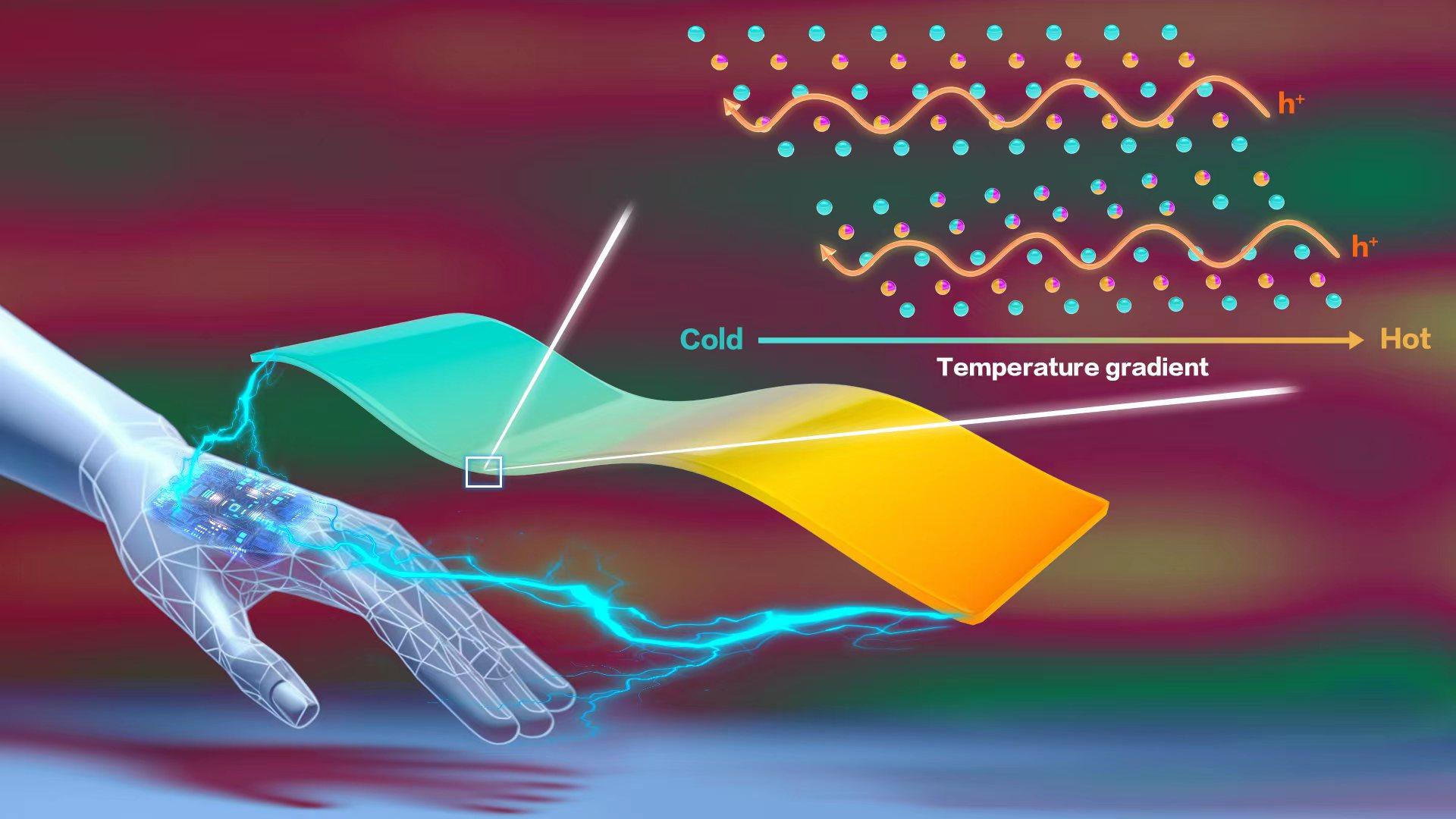

Thermoelectric technique takes advantage of the Seebeck effect, where a temperature difference generates a voltage that can be used to power devices. The versatility of this technique also provides great potential in wearable consumer products since the temperature difference is so universal between the environment and the human body. However, most commercially available TEs are intrinsically brittle with literally no or little flexibility, thus excluding them from being adaptable to body movement. Developing high thermoelectric performance TE materials and devices with sufficient pliability and optimal stretchability is crucial for the new vast market of wearable applications.

Chair Professor Jiaqing He from the Department of Physics at the Southern University of Science and Technology (SUSTech) has been doing leading work on thermoelectric techniques for decades with remarkable achievements both scientifically and commercially. His research team, the He group, recently managed to prepare a flexible TE film with the highest power factor to date.

Their work, entitled “Staggered-layer-boosted flexible Bi2Te3 films with high thermoelectric performance”, has been published in Nature Nanotechnology.

“The idea of producing a thin film from single crystalline TE material is brilliant, and the design is exquisite”, said the first author Dr. Yao Lu, who was a postdoctoral fellow in the He group and currently holds an Associate Professor position at the Dongguan University of Technology (DGUT).

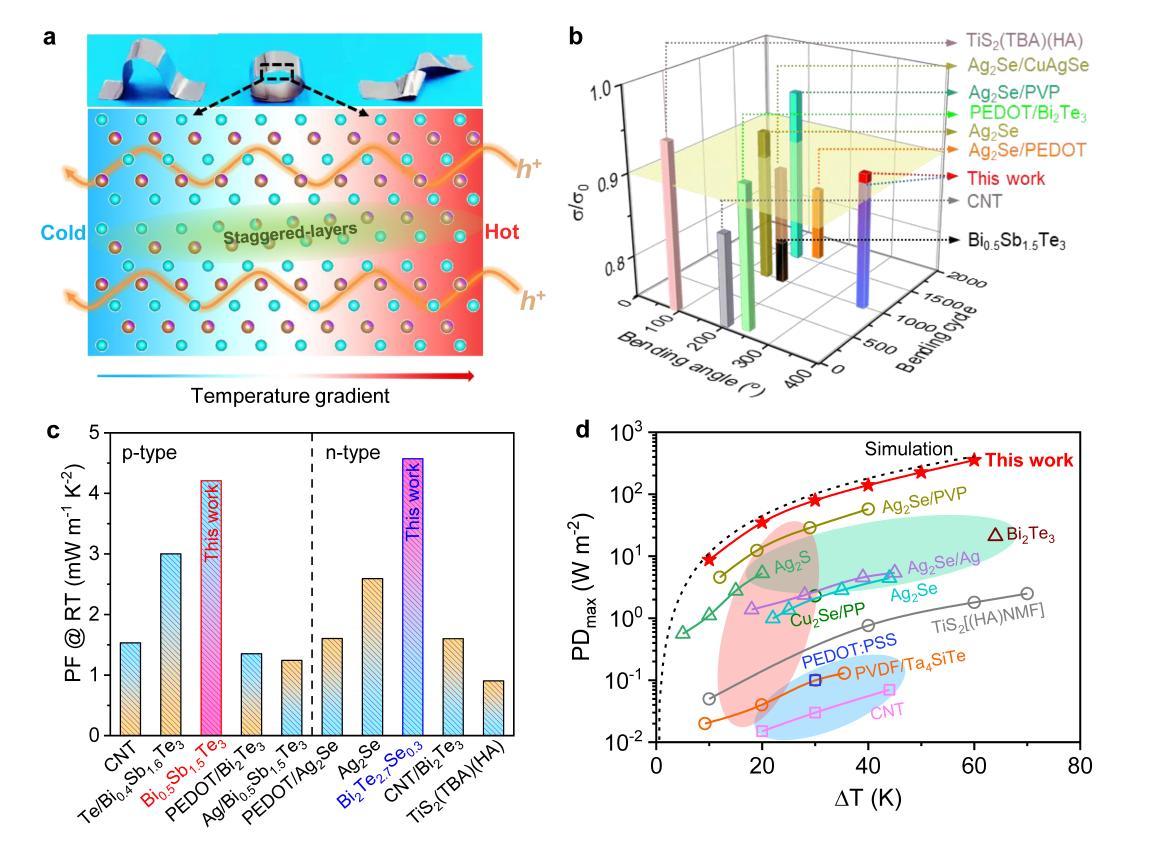

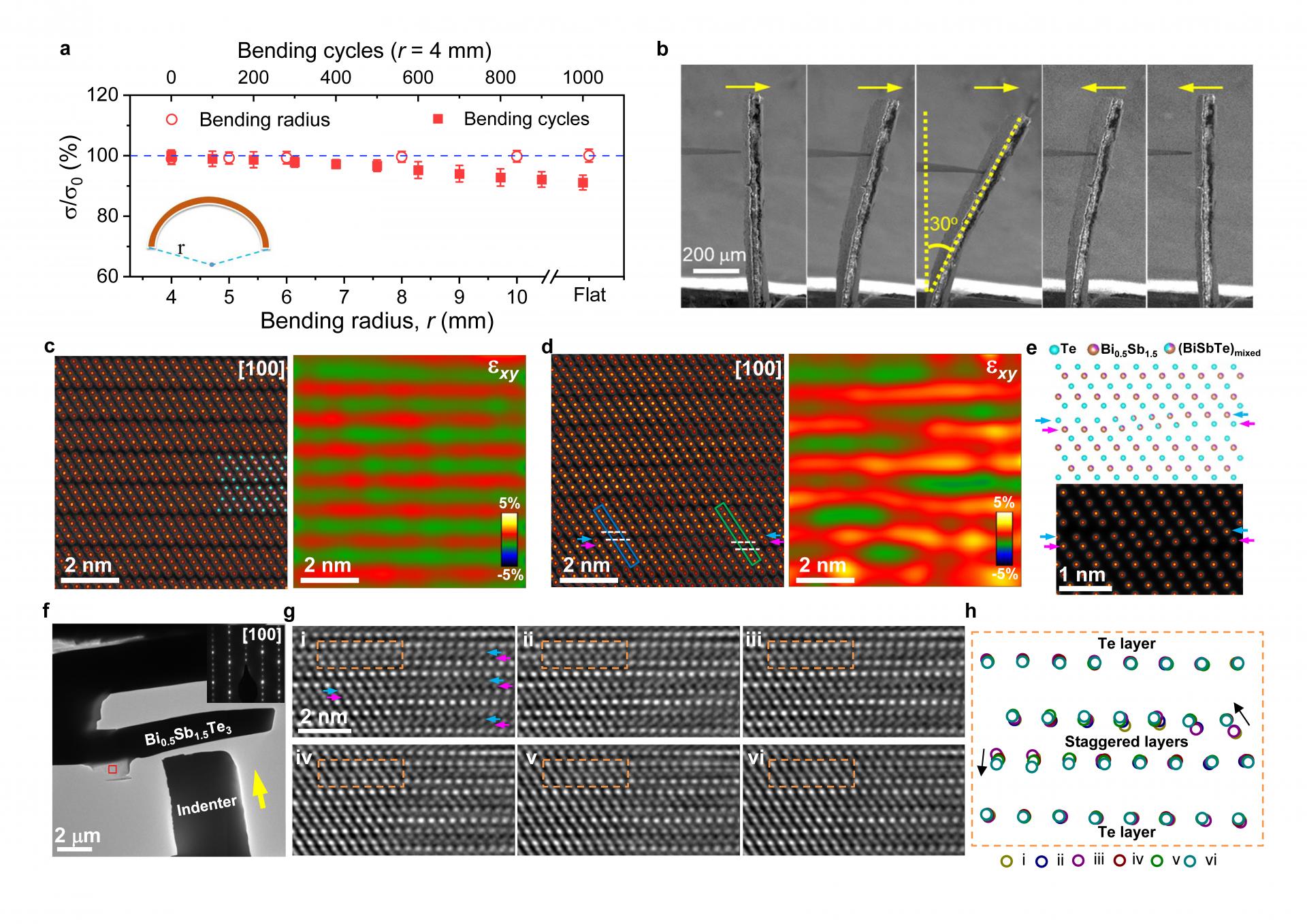

The group presented a universal strategy to develop p- and n-type Bi2Te3-based flexible films peeled off from Bi0.5Sb1.5Te3 (BST) and Bi2Te2.7Se0.3 (BTS) single crystals (SC). The film inherits the high-power factor (PF) of the Bi2Te3 SC with an extra flexibility advantage, as demonstrated by repeatable bending over 1000 times at a bending angle of 4 mm. Even with the harsh bending test, the film only loses 9% of its initial conductivity, which outperforms all reported Bi2Te3-based films. In-situ high-resolution transmission electron microscopy reveals a unique stagger-layer structure in the preparation of the film that originates from the atomic exchange between Te and Bi/Sb in the vicinity of the van der Waals gap. The atomic displacement is crucial to the flexibility of the film, as supported by the in-situ analysis of the structure and strain of the stagger layer.

The researchers simulated the atomic exchange in the transition from common structures to staggered-layer structures by computing the relative forming energy using density functional theory calculations. Despite the defects, the TE film inherits the high PF of the SC with the highest room temperature PF value of 4.2 mW m-1 K-2 for p-type and 4.6 mW m-1 K-2 for-n type films. The introduction of staggered structures caused the Fermi level to shift into the conduction band, as confirmed by the effective mass change given by the band structure computation. Such a staggered layer acts as a donor, providing electrons while suppressing holes, which leads to a decrease in carrier concentration in p-type films and an increase in carrier concentration in n-type films. The synergistic change in n and effective mass led to consistent electrical conductivity and Seebeck coefficient in the films after exfoliation from the SC.

The group also illustrates the potential of a flexible TE generator by assembling the p- and n-type films to give an output voltage and maximum power density of 111 mV and 32 W m-2 at a temperature difference of 60 K. The work showcases state-of-the-art TE performance as well as provides an insightful scientific understanding of the structure-property relation for semiconductors, which will facilitate the development of TE devices for wearable electronics.

Figure 1. Exceptional flexibility and high thermoelectric performance of Bi2Te3-based films

Figure 2. Macroscopic, microscopic, and atomic-scale in-situ observations of staggered-layer-boosted flexibility for p-type Bi0.5Sb1.5Te3 films

Figure 3. Temperature-dependent thermoelectric properties and DFT electronic band structures of the p- and n-type single crystals and films

Associate Professor Yao Lu (former postdoctoral fellow at SUSTech) at the University of Dongguan University of Technology, Ph.D. student Yi Zhou, Research Assistant Professors Wu Wang and Mingyuan Hu are the first author of this work. Chair Professor Jiaqing He is the sole corresponding author.

The work was supported by the National Natural Science Foundation of China (NSFC), Natural Science Foundation of Guangdong Province, Leading Talents of the Guangdong Province Program, and the Science, Technology and Innovation Commission of Shenzhen Municipality.

Paper link:

The He group webpage: